& does relevant recommendations: 【 casing expansion pipe, corrugated expansion pipe, reducing rubber joint 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

官网登录入口.jpg)

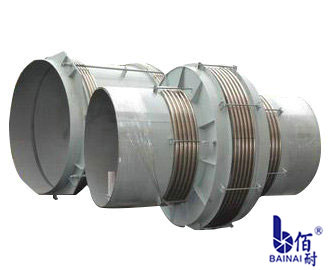

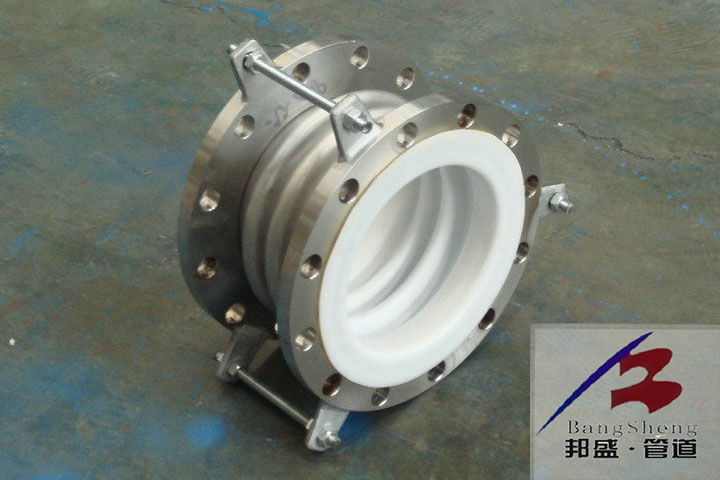

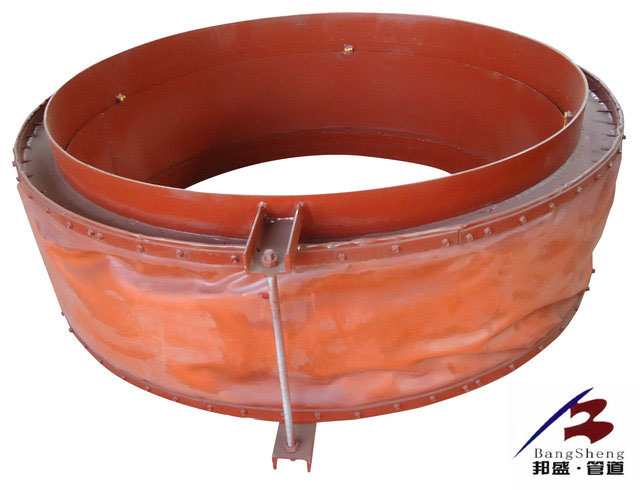

Lining ptfe compensator is introduced

Lining ptfe compensator is through the special processing methods, change the characteristics of the past can not crooked pipe, resistant to various concentration of acid, alkali, salt, but also the pressure of the stainless steel compensator, has the advantages of not afraid of collision. It can be used to connect the mechanical lower graphite, ceramic glass pipe, as a tank, storage tank, to the container or the reaction kettle, discharge tube, pipe misalignment can be connected or used to balance due to weather or other reasons cause displacement of the pipeline, a dimensional change or used to eliminate the high frequency mechanical vibration. In special occasions but also for tubular reactor or heat exchanger, and so on.

Lining ptfe compensator according to the special requirements of users, corrosion resistance, high temperature resistant, etc.) design, used in chemical industry, medicine, food and other industries of ?

The performance characteristics of ptfe compensator

Pressure: vacuum ~ 0.1 MPa

Round: (~ DN5000

Rectangle: arbitrary cross section

Outside the body for the stainless steel metal compensator

Provide: DN25-6000 - mm

For fatigue life: 3000 times

Pressure rating: PN0.6, PN1.0, PN1.6, PN2.5, PN4.0 MPa