& does relevant recommendations: 【 rubber shock absorber, pipeline expansion, pine set limit to pull expansion 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

Pipeline corrugated pipe is introduced

Corrugated pipe of the pipe as elastic sealing parts, the first to meet strength conditions, namely the maximum stress is less than allowable stress under the given conditions. Allowable stress can be obtained from limit stress divided by the safety factor. According to the working conditions of the corrugated pipe and its application requirements, can be the yield strength, ultimate stress can also be a corrugated pipe buckling critical stress, or fatigue strength. To compute bellows maximum working stress must stress distribution analysis of corrugated pipe wall.

Pipeline bellows design is the theory basis of plate and shell theory, material mechanics, computational mathematics, etc. Pipe bellows design parameters is more, because the pipeline corrugated pipe in the system use different, its design and calculation of key is different also.

The classification of the corrugated pipe pipe

Pipeline bellows from could be divided into two kinds of metal and nonmetal material.

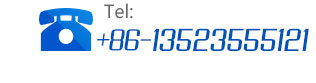

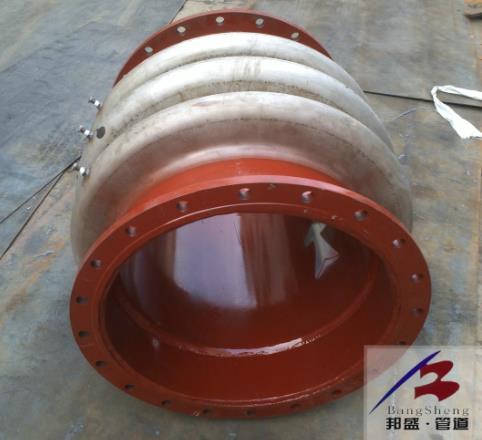

1. Metal corrugated pipe is made up of work constitute the main body of corrugated pipe (a kind of elastic element) and the end of tubes, stents, flange, pipe and other accessories, belongs to a kind of compensation components. Use its work subject bellows telescopic deformation effectively, to absorb piping, pipe, container, etc is produced by the reason of heat bilges cold shrink and the size of the change, or compensation pipeline, pipe, container, etc of axial, lateral and angular displacement, vibration can also be used for noise reduction, widely used in modern industry.

2. Non-metallic bellows can compensate the pipeline axial, lateral and angular displacement, with no thrust bearing design, simplify, corrosion resistance, high temperature resistant, vibration, etc ?