& does relevant recommendations: 【 stainless steel corrugated compensator, buried corrugated compensator, rubber compensator 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

官网登录入口1.jpg)

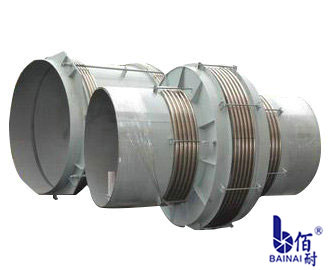

Steel flexible waterproof sleeve compensator is introduced

Steel flexible waterproof sleeve compensator is thermal fluid pipeline compensator, is mainly used for straight pipe linings, suitable for hot water, steam, oil medium, through the sliding movement of the sliding sleeve external sleeve, compensation of thermal expansion.

The structure of the steel flexible waterproof sleeve compensator

1, flexible packing materials: asphalt flax, polystyrene board, PVC foam plastic board.

2, sealant, polysulfide sealant, polyurethane sealant.

3, casing wear wall place, in case of the concrete wall should be partial to the concrete wall, the casting range should be colorful ring diameter (D5) 200, and must be poured casing a fixed in the wall.

4, wear in the concrete wall thickness ?

5, the weight of the casing with L = 300 calculation, such as wall thickness is more than 300, should be calculated separately.

The use of steel flexible waterproof sleeve compensator

1, when the meet the water is corrosive medium, can be used to block material gap seal.

2, casing wear wall place, in case of the concrete wall should be partial to the concrete wall, the casting range should be colorful ring diameter (D5) 200, and must be poured casing a fixed in the wall.

3, wear in the concrete wall thickness shall be not less than 300, otherwise should be made on both sides of the side wall thickening or thickening, thickening of the diameter of the part at least of D5 + 200.

4, the weight of the casing with L = 300 calculation, such as wall thickness is more than 300, should be calculated separately.