& does relevant recommendations: 【 foraged rubber joint, soft rubber joints, non-metallic compensator fabric 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

官网登录入口(1).jpg)

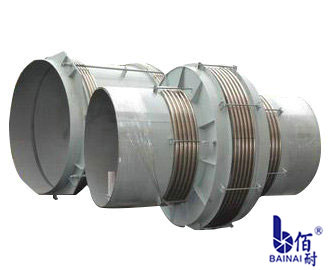

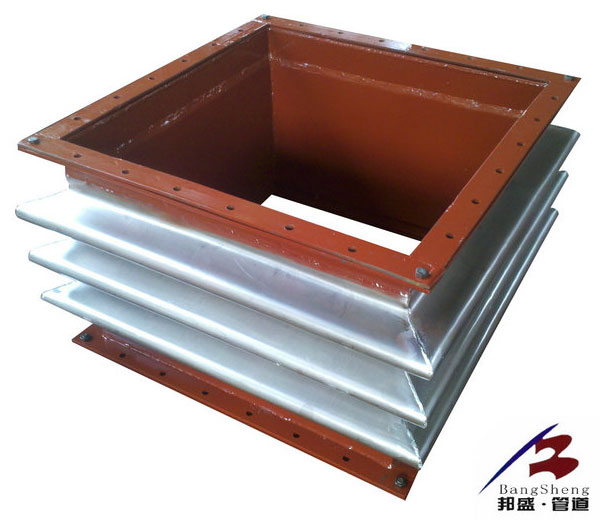

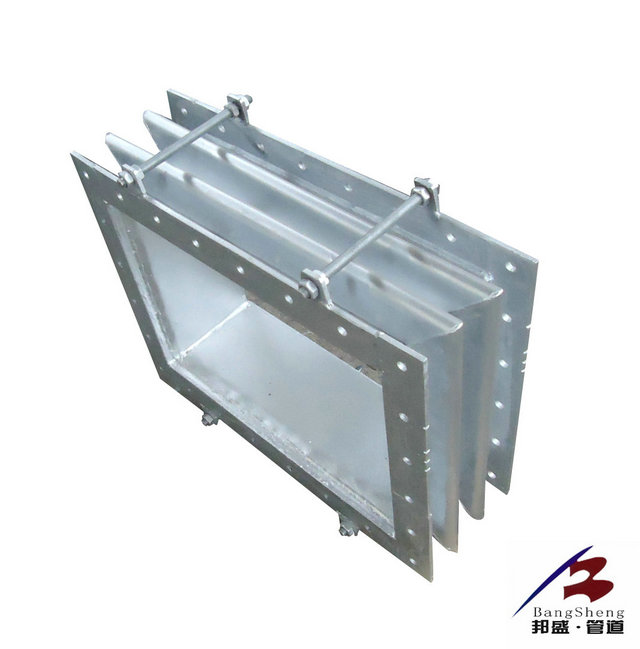

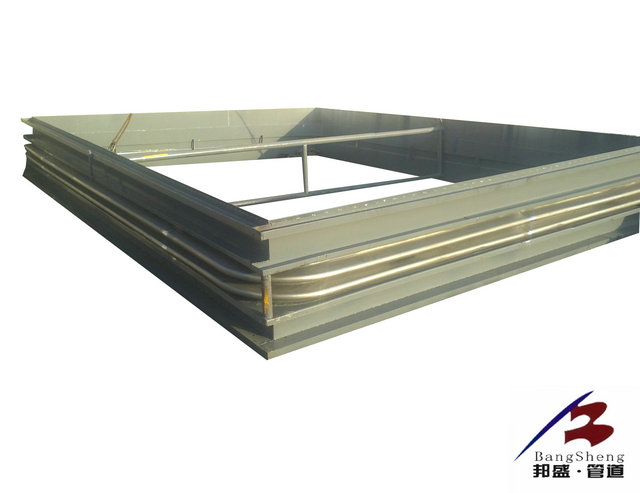

Rectangular metal compensator is introduced

Rectangular metal compensator is a compensating element, using its work subject bellows telescopic deformation effectively, to absorb piping, pipe, container, etc is produced by the reason of heat bilges cold shrink and the size of the change, or compensation pipeline, pipe, container, etc of the axial, lateral and angular displacement. Can also be used for noise reduction vibration reduction.

Rectangular metal compensator installation requirements

1, the compensator before installation should check its type, specification and pipeline configuration, must comply with the design requirements.

2, with inner sleeve compensator should pay attention to the inner sleeve of the direction of the cheese is consistent with the flow direction of medium.

3, need to be "cold" tight compensator, predeformation auxiliary components should be used in pipe installation is removed.

4, it is forbidden to use corrugated compensator deformation method to adjust the pipeline installation error, so as not to affect the normal function of the compensator, reduce the service life of the components and piping, equipment, supporting the load.

5, the installation process, do not allow the welding slag splash to the shell surface, do not allow the wave shell by other mechanical damage.