& does relevant recommendations: 【 steel expansion pipe, cast iron expansion, mesh expansion 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

官网登录入口(1).jpg)

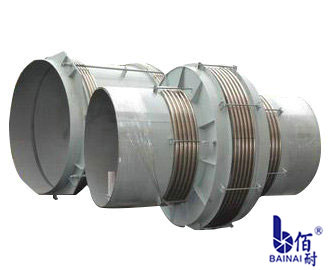

Rotating compensator is introduced

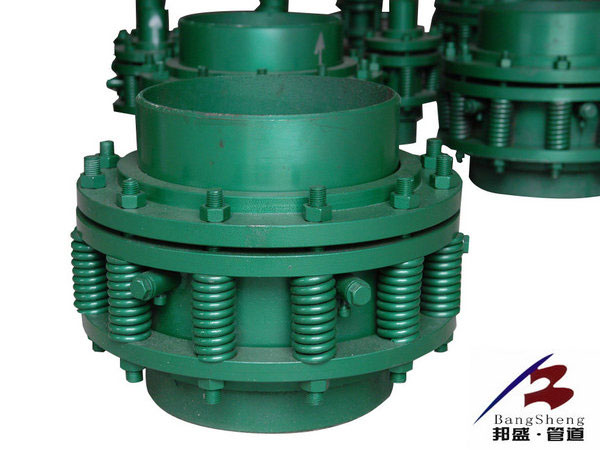

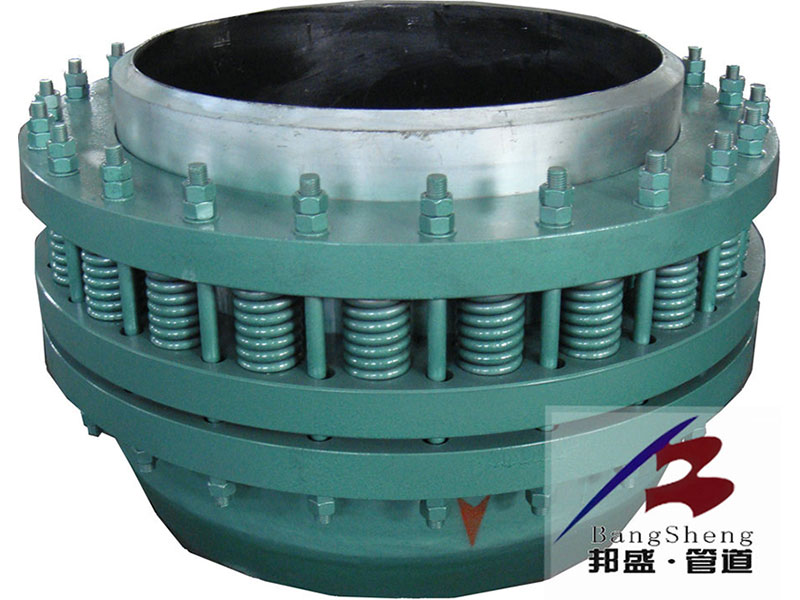

Rotating compensator is a new type of heat pipe heat expansion areas of compensator. It is used by flexible packing cavity packing seal. Every revolution of the products in use process packing will wear a bit, when the wear reaches a certain value, the amount of the product would be a leak. Rotating compensator for above packing compression flange increases a set of spring, when there was a trace of wear packing, depending on the compression spring tension compensation, thus prolong product leak (leak time delay 3-5 years). When wear more than spring tension compensation amount, just pull the spring compression flange at the top of the nut can, do not need to repair, stopping air run, often not easy to produce leaks, thereby greatly improving

Rotating compensator structure mainly has the overall seal seat, gland, size head, anti-friction centering bearing, sealing materials, rotating cylinder and other artifacts, installed on the heat pipe to two or more group to group, form the relatively rotation absorption pipeline thermal displacement, so as to reduce the stress of pipeline.

Rotating compensator in the line according to the 150 ~ 500 m to install a set of commonly (according to determine the natural terrain), there are ten a variety of installations, according to the pipeline to determine the decorate a form. After using this type compensator, fixed stent spacing increases, in order to avoid section flexure to appropriately increase the guide bracket, in order to reduce the friction resistance of pipeline operation, the sliding bracket shall be installed on the rolling bearing.

The advantages of rotating compensator

(1), a large amount of compensation, according to the natural topography and the strength of pipe layout, the largest group of compensator can compensate 500 m section;

(2), do not produce the blind flange force generated by the medium pressure, fixed bracket can be done is very small, especially suitable for large caliber pipe;

(3), the sealing performance is superior, long-term operation does not need to maintain;

(4), save investment greatly;

(5), design and calculation is convenient;

(6), rotating compensator can be installed on the exchanger steam and hot water exchanger, can save investment and improve operation security.